Asset Tracking: Industrial IoT Solutions for Improved Outcomes

In a previous blog, we spoke about the need for high-performance computing at the edge of the network for a video analytics IoT use-case. We will continue along the same vein in this article, but will look at the transformation happening at Industrial IoT in the asset tracking, monitoring, and maintenance marketplace. While this is an extremely broad subject with thousands of use-cases, we will make an effort to look at it from an Industrial IoT perspective with a few examples.

Why is asset tracking important?

Most companies that have their valuable assets distributed over a large geographical area have to contend with a host of problems that affect their productivity, operational efficiencies, staffing, costs, and ultimately their bottom-line, among other things. These issues could manifest in the form of poor health of their assets, theft, pilferage, damage due to natural calamities, underperformance, safety, productivity, counterfeiting, leakage, excessive pollution and carbon emissions to outright loss of perishable goods, and the list goes on and on. In the past, there haven’t been cost-effective ways to monitor these assets to be able to take timely and corrective action or act on deep insights for better outcomes. Meaningful data collection has been quite expensive as well. Not anymore.

With the explosion of low-cost sensors (pressure, temperature, humidity, image, etc.), location based services with GPS, affordable connectivity (LTE/WiFi/BT/etc.) and gateways, more and more assets are being equipped with tracking devices, sensors, and actuators. The sheer volume of devices with tracking capabilities runs into the billions and is growing every day. Assets can come in the form of perishable goods (cold chain from the farm to the grocery store); leased construction, agricultural, and mining equipment; government movable assets, public transport, railroad rolling stock, airline, military, shipping lines, bus/van/car/trailer fleet operators, livestock, and more.

Tracking hazardous materials takes a totally new hue, be it storage (remote monitoring of radioactive materials/spent fuel  under the earth) or movement of crude/fossil fuels/chemicals on railroads, oil and gas tankers, and so on. Spillage or leakage can cause catastrophic damage to the environment and health of humans and wildlife like we’ve witnessed several times in the recent past. Tracking such hazardous materials and movement especially in thickly populated areas with proactive monitoring by multiple agencies (HAZMAT/Law enforcement/Fire/Local government bodies) can nip a major catastrophe in the bud.

Of late, service providers, insurance companies, and auto manufacturers are connecting vehicles with telematics at a frenetic pace to track driver/user behavior, driving patterns, and health of automobiles. These aim to help improve safety, charge usage-based insurance premiums, provide remote vehicle diagnostics, and minimize downtime with scheduled preventative maintenance.

Asset tracking use cases

Transportation, Renewable Energy, and more

under the earth) or movement of crude/fossil fuels/chemicals on railroads, oil and gas tankers, and so on. Spillage or leakage can cause catastrophic damage to the environment and health of humans and wildlife like we’ve witnessed several times in the recent past. Tracking such hazardous materials and movement especially in thickly populated areas with proactive monitoring by multiple agencies (HAZMAT/Law enforcement/Fire/Local government bodies) can nip a major catastrophe in the bud.

Of late, service providers, insurance companies, and auto manufacturers are connecting vehicles with telematics at a frenetic pace to track driver/user behavior, driving patterns, and health of automobiles. These aim to help improve safety, charge usage-based insurance premiums, provide remote vehicle diagnostics, and minimize downtime with scheduled preventative maintenance.

Asset tracking use cases

Transportation, Renewable Energy, and more

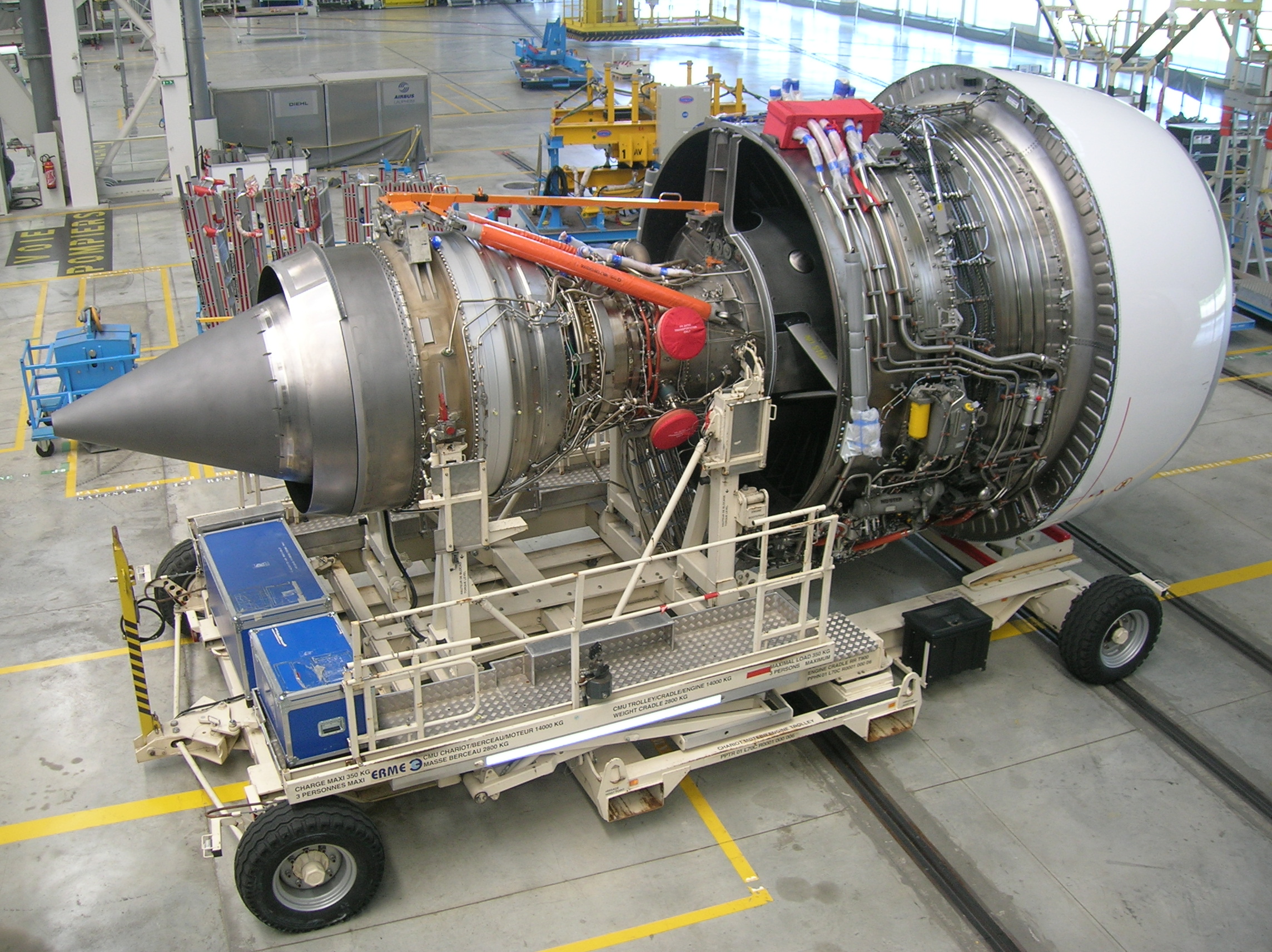

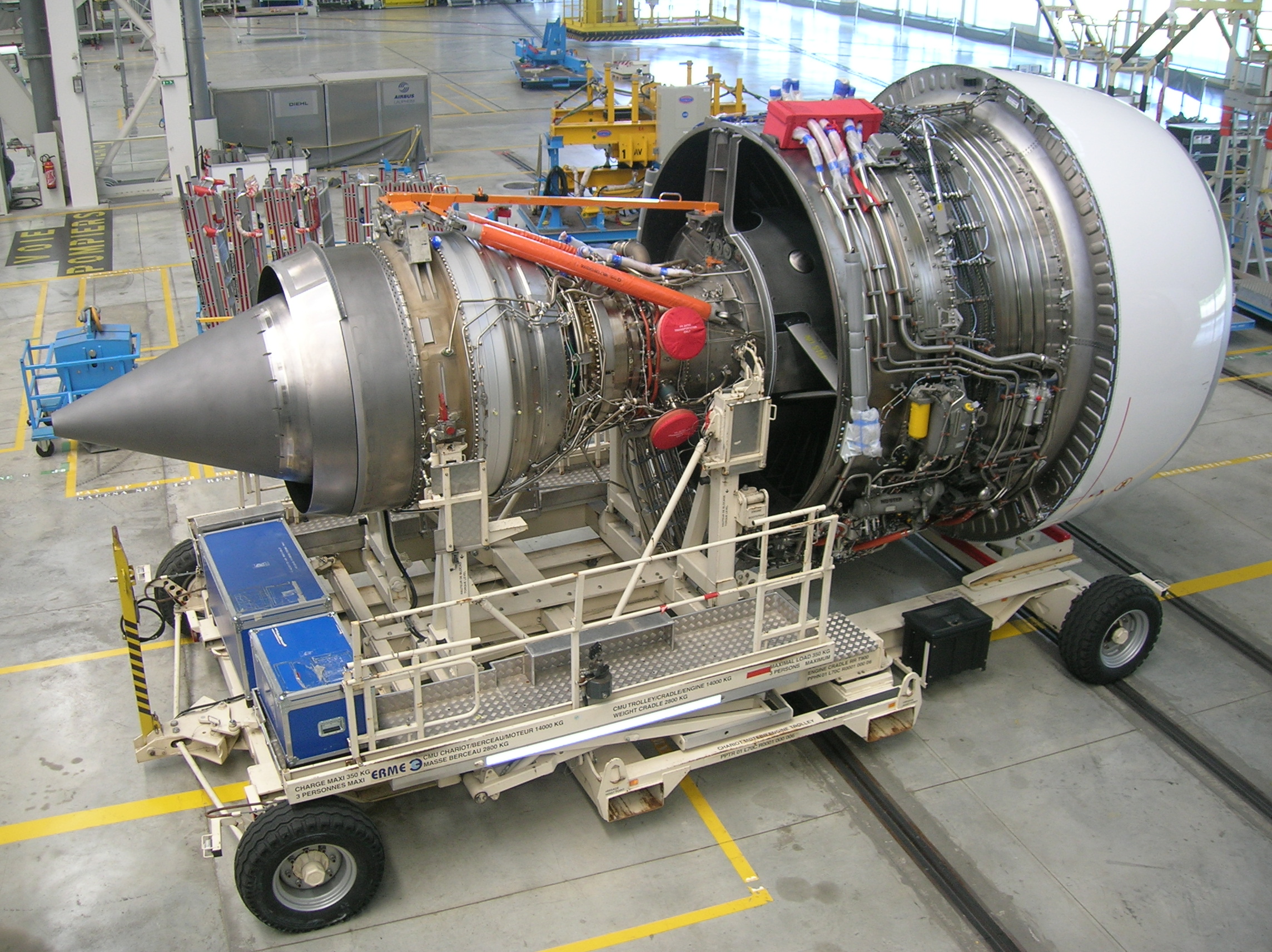

GE is renowned for tracking the health of all of its jet engine and wind turbine installations world-wide. With terabytes data collected from these expensive assets, predictive analytics of its performance leading to better fuel efficiencies and lower carbon footprint, preventive maintenance scheduling, and reduced operational costs during planned downtimes are achieved.

We had earlier discussed remote asset tracking in the international space station (ISS) with NASA’s Astrobee, the next generation free-flying robot, which will use computer vision algorithms and deep learning to accurately identify objects without human intervention. The Astrobee will also perform an automated inventory control (the ISS has hundreds of objects that will be RFID tagged), making it easier to keep track of things.

Construction, mining, and infrastructure inspection

A large construction and mining equipment leasing company is migrating to an IoT enabled asset tracking system that provides a real-time dashboard with easily accessible location and performance data. The firm was incurring losses due to theft of air compressors from construction and storage sites, inefficient fuel usage, and miss-allocation of assets to revenue paying customers. By installing a connected GPS-based asset tracking system with fuel consumption sensors, they were able to monitor the compressors on a real-time basis; leading to better accuracy in usage-based billing and happier customers. We are increasingly seeing such assets being offered “as-a-service” (a-a-S), and service-level-agreements (SLAs) come into play, which means real-time monitoring of an asset’s performance and health is hugely critical. Location based monitoring is also helping them optimize asset movement/re-assignment to nearby construction sites, reducing transportation costs and better utilization of revenue generating assets. Geo-fencing a group of these compressors also ensures an automated path to recovery by interfacing effectively with law-enforcement to retrieve stolen assets or when dispatch sends equipment to incorrect locations.

GE is renowned for tracking the health of all of its jet engine and wind turbine installations world-wide. With terabytes data collected from these expensive assets, predictive analytics of its performance leading to better fuel efficiencies and lower carbon footprint, preventive maintenance scheduling, and reduced operational costs during planned downtimes are achieved.

We had earlier discussed remote asset tracking in the international space station (ISS) with NASA’s Astrobee, the next generation free-flying robot, which will use computer vision algorithms and deep learning to accurately identify objects without human intervention. The Astrobee will also perform an automated inventory control (the ISS has hundreds of objects that will be RFID tagged), making it easier to keep track of things.

Construction, mining, and infrastructure inspection

A large construction and mining equipment leasing company is migrating to an IoT enabled asset tracking system that provides a real-time dashboard with easily accessible location and performance data. The firm was incurring losses due to theft of air compressors from construction and storage sites, inefficient fuel usage, and miss-allocation of assets to revenue paying customers. By installing a connected GPS-based asset tracking system with fuel consumption sensors, they were able to monitor the compressors on a real-time basis; leading to better accuracy in usage-based billing and happier customers. We are increasingly seeing such assets being offered “as-a-service” (a-a-S), and service-level-agreements (SLAs) come into play, which means real-time monitoring of an asset’s performance and health is hugely critical. Location based monitoring is also helping them optimize asset movement/re-assignment to nearby construction sites, reducing transportation costs and better utilization of revenue generating assets. Geo-fencing a group of these compressors also ensures an automated path to recovery by interfacing effectively with law-enforcement to retrieve stolen assets or when dispatch sends equipment to incorrect locations.

Another innovative company that makes Ultra HD drone-mounted cameras targeted for infrastructure monitoring has eliminated 1 in 3 tower (wireless, broadcast, and other aerial structures) climbs. Professional tower climbers have had to manually inspect structures to debug issues or monitor the health of assets on these towers. What used to be a manual, laborious, and time-consuming job (not to mention safety/need to wear a harness) to track and maintain towers has now become a routine and frictionless exercise, thanks to cloud-connected inspection photography, with the images/videos accessible to multiple parties instantaneously. Tower owners, tenants, and climbers can now get safer, faster, and cheaper inspections done from close-range and any imaginable angle!

Farming and Agriculture

A pig farmer in Austria keeps track of his animals, whether they are in the barn, or in the field. Advanced image processing can now not only count, but also estimate the weight of the pigs (without physical weighing the animals) and contact less temperature sensors help monitor the health of these assets. Other inexpensive livestock wearable electronic collars can now keep track of everything including cattle vitals, location of stray calves, etc., helping lower labor costs or visits to the vet. These wearable collars have sensors to monitor and catch health issues early before it becomes a larger problem such as the need for antibiotics or the spread of diseases within the herd. These devices communicate data periodically to barn based solar powered gateways which transmit it to the cloud for further processing and provide access to actionable dashboards via mobile device apps.

Retailing

Another interesting area is people counting in retail and public places leading to analytics that can help improve outcomes for both consumers and retail establishments. Large retailers that have

Another innovative company that makes Ultra HD drone-mounted cameras targeted for infrastructure monitoring has eliminated 1 in 3 tower (wireless, broadcast, and other aerial structures) climbs. Professional tower climbers have had to manually inspect structures to debug issues or monitor the health of assets on these towers. What used to be a manual, laborious, and time-consuming job (not to mention safety/need to wear a harness) to track and maintain towers has now become a routine and frictionless exercise, thanks to cloud-connected inspection photography, with the images/videos accessible to multiple parties instantaneously. Tower owners, tenants, and climbers can now get safer, faster, and cheaper inspections done from close-range and any imaginable angle!

Farming and Agriculture

A pig farmer in Austria keeps track of his animals, whether they are in the barn, or in the field. Advanced image processing can now not only count, but also estimate the weight of the pigs (without physical weighing the animals) and contact less temperature sensors help monitor the health of these assets. Other inexpensive livestock wearable electronic collars can now keep track of everything including cattle vitals, location of stray calves, etc., helping lower labor costs or visits to the vet. These wearable collars have sensors to monitor and catch health issues early before it becomes a larger problem such as the need for antibiotics or the spread of diseases within the herd. These devices communicate data periodically to barn based solar powered gateways which transmit it to the cloud for further processing and provide access to actionable dashboards via mobile device apps.

Retailing

Another interesting area is people counting in retail and public places leading to analytics that can help improve outcomes for both consumers and retail establishments. Large retailers that have presence both online and in physical stores are focusing on the omnichannel customer shopping experience. How many times have you been to a store and had to walk out because you didn’t find a sales person that could answer questions or help identify the right product for your needs? Optimal staffing has always been a major concern for retailers (in offline physical stores), with under/over staffing contributing to lost sales opportunities and increased labor costs. A few companies have recently come out with tracking devices aimed at ultimately improving customer experiences in retail shopping. By tracking both the consumer traffic and the staffing associated with specific times of the day, predictive analytics can now help fine-tune staffing assignments (and putting the right sales people) to meet demand, leading to increased overall revenues and reduced labor costs.

With the introduction of electronic voting machines in many democracies world-wide, monitoring these extremely valuable assets becomes critical since they may be deployed in hard-to-reach villages, mountainous regions, and in countries with scattered islands. GPS based asset tracking with geo-fences also ensures these voting machines don’t land up in the wrong hands or locations. Tracking the well-being of these devices is also paramount to ensure they are not tampered with and reach secure holding areas after polling is complete.

Benefits of real-time asset tracking

The benefits of real-time asset tracking, as you can see, are numerous. We’ve listed a few here, but we will only be scratching the surface as innovative Industrial IoT solutions are reshaping a multitude of verticals. Achieving higher levels of performance by reducing downtime, scheduling preventative maintenance, obtaining real-time intelligence of a remote asset’s operation, all contribute towards increasing profits and improving customer satisfaction. This is especially true when several industries shift from selling customers products outright to offering them “as-a-service” where honoring service level agreements will have a direct bearing on revenue generation and profitability. Real-time access to data from remote sensors and tracking devices provide the ability to take corrective action before a loss or unplanned downtime can occur.

Fleet management companies, for example, benefit from access to real-time traffic and location of their assets so that routes can be optimized by dispatch, reducing idling and fuel/labor costs. Vehicle based telematics allows tracking the health of automobiles and over-the-air diagnostics help schedule proper maintenance. For the cold-chain industry, real-time monitoring of temperature from production facilities to refrigerated trucks to cold warehouses to purchase points can mean the difference between loss or on-time delivery of perishable goods.

Innovative Industrial IoT Solutions for Asset Tracking

presence both online and in physical stores are focusing on the omnichannel customer shopping experience. How many times have you been to a store and had to walk out because you didn’t find a sales person that could answer questions or help identify the right product for your needs? Optimal staffing has always been a major concern for retailers (in offline physical stores), with under/over staffing contributing to lost sales opportunities and increased labor costs. A few companies have recently come out with tracking devices aimed at ultimately improving customer experiences in retail shopping. By tracking both the consumer traffic and the staffing associated with specific times of the day, predictive analytics can now help fine-tune staffing assignments (and putting the right sales people) to meet demand, leading to increased overall revenues and reduced labor costs.

With the introduction of electronic voting machines in many democracies world-wide, monitoring these extremely valuable assets becomes critical since they may be deployed in hard-to-reach villages, mountainous regions, and in countries with scattered islands. GPS based asset tracking with geo-fences also ensures these voting machines don’t land up in the wrong hands or locations. Tracking the well-being of these devices is also paramount to ensure they are not tampered with and reach secure holding areas after polling is complete.

Benefits of real-time asset tracking

The benefits of real-time asset tracking, as you can see, are numerous. We’ve listed a few here, but we will only be scratching the surface as innovative Industrial IoT solutions are reshaping a multitude of verticals. Achieving higher levels of performance by reducing downtime, scheduling preventative maintenance, obtaining real-time intelligence of a remote asset’s operation, all contribute towards increasing profits and improving customer satisfaction. This is especially true when several industries shift from selling customers products outright to offering them “as-a-service” where honoring service level agreements will have a direct bearing on revenue generation and profitability. Real-time access to data from remote sensors and tracking devices provide the ability to take corrective action before a loss or unplanned downtime can occur.

Fleet management companies, for example, benefit from access to real-time traffic and location of their assets so that routes can be optimized by dispatch, reducing idling and fuel/labor costs. Vehicle based telematics allows tracking the health of automobiles and over-the-air diagnostics help schedule proper maintenance. For the cold-chain industry, real-time monitoring of temperature from production facilities to refrigerated trucks to cold warehouses to purchase points can mean the difference between loss or on-time delivery of perishable goods.

Innovative Industrial IoT Solutions for Asset Tracking

Remote asset tracking and monitoring solutions will come in all forms of shapes, sizes, and capabilities, depending on cost, conditions, context, geo location, available communication infrastructure, type of sensors required, etc. so no one size will fit all. This adds to the complexity of the hardware and software solutions that need to be customized for a given end-user or application. In many cases, the IoT edge device will need significant compute power so as to not upload all the data into the cloud for processing. This will be dictated by an end-application that would need the data to be close to the edge of the network or gateways for security, identity protection, and availability of connectivity, cost savings, and more. Easily configurable and customizable Industrial IoT frameworks will be able to deliver optimized solutions for asset tracking.

Remote asset tracking and monitoring solutions will come in all forms of shapes, sizes, and capabilities, depending on cost, conditions, context, geo location, available communication infrastructure, type of sensors required, etc. so no one size will fit all. This adds to the complexity of the hardware and software solutions that need to be customized for a given end-user or application. In many cases, the IoT edge device will need significant compute power so as to not upload all the data into the cloud for processing. This will be dictated by an end-application that would need the data to be close to the edge of the network or gateways for security, identity protection, and availability of connectivity, cost savings, and more. Easily configurable and customizable Industrial IoT frameworks will be able to deliver optimized solutions for asset tracking.

under the earth) or movement of crude/fossil fuels/chemicals on railroads, oil and gas tankers, and so on. Spillage or leakage can cause catastrophic damage to the environment and health of humans and wildlife like we’ve witnessed several times in the recent past. Tracking such hazardous materials and movement especially in thickly populated areas with proactive monitoring by multiple agencies (HAZMAT/Law enforcement/Fire/Local government bodies) can nip a major catastrophe in the bud.

Of late, service providers, insurance companies, and auto manufacturers are connecting vehicles with telematics at a frenetic pace to track driver/user behavior, driving patterns, and health of automobiles. These aim to help improve safety, charge usage-based insurance premiums, provide remote vehicle diagnostics, and minimize downtime with scheduled preventative maintenance.

Asset tracking use cases

Transportation, Renewable Energy, and more

under the earth) or movement of crude/fossil fuels/chemicals on railroads, oil and gas tankers, and so on. Spillage or leakage can cause catastrophic damage to the environment and health of humans and wildlife like we’ve witnessed several times in the recent past. Tracking such hazardous materials and movement especially in thickly populated areas with proactive monitoring by multiple agencies (HAZMAT/Law enforcement/Fire/Local government bodies) can nip a major catastrophe in the bud.

Of late, service providers, insurance companies, and auto manufacturers are connecting vehicles with telematics at a frenetic pace to track driver/user behavior, driving patterns, and health of automobiles. These aim to help improve safety, charge usage-based insurance premiums, provide remote vehicle diagnostics, and minimize downtime with scheduled preventative maintenance.

Asset tracking use cases

Transportation, Renewable Energy, and more

GE is renowned for tracking the health of all of its jet engine and wind turbine installations world-wide. With terabytes data collected from these expensive assets, predictive analytics of its performance leading to better fuel efficiencies and lower carbon footprint, preventive maintenance scheduling, and reduced operational costs during planned downtimes are achieved.

We had earlier discussed remote asset tracking in the international space station (ISS) with NASA’s Astrobee, the next generation free-flying robot, which will use computer vision algorithms and deep learning to accurately identify objects without human intervention. The Astrobee will also perform an automated inventory control (the ISS has hundreds of objects that will be RFID tagged), making it easier to keep track of things.

Construction, mining, and infrastructure inspection

A large construction and mining equipment leasing company is migrating to an IoT enabled asset tracking system that provides a real-time dashboard with easily accessible location and performance data. The firm was incurring losses due to theft of air compressors from construction and storage sites, inefficient fuel usage, and miss-allocation of assets to revenue paying customers. By installing a connected GPS-based asset tracking system with fuel consumption sensors, they were able to monitor the compressors on a real-time basis; leading to better accuracy in usage-based billing and happier customers. We are increasingly seeing such assets being offered “as-a-service” (a-a-S), and service-level-agreements (SLAs) come into play, which means real-time monitoring of an asset’s performance and health is hugely critical. Location based monitoring is also helping them optimize asset movement/re-assignment to nearby construction sites, reducing transportation costs and better utilization of revenue generating assets. Geo-fencing a group of these compressors also ensures an automated path to recovery by interfacing effectively with law-enforcement to retrieve stolen assets or when dispatch sends equipment to incorrect locations.

GE is renowned for tracking the health of all of its jet engine and wind turbine installations world-wide. With terabytes data collected from these expensive assets, predictive analytics of its performance leading to better fuel efficiencies and lower carbon footprint, preventive maintenance scheduling, and reduced operational costs during planned downtimes are achieved.

We had earlier discussed remote asset tracking in the international space station (ISS) with NASA’s Astrobee, the next generation free-flying robot, which will use computer vision algorithms and deep learning to accurately identify objects without human intervention. The Astrobee will also perform an automated inventory control (the ISS has hundreds of objects that will be RFID tagged), making it easier to keep track of things.

Construction, mining, and infrastructure inspection

A large construction and mining equipment leasing company is migrating to an IoT enabled asset tracking system that provides a real-time dashboard with easily accessible location and performance data. The firm was incurring losses due to theft of air compressors from construction and storage sites, inefficient fuel usage, and miss-allocation of assets to revenue paying customers. By installing a connected GPS-based asset tracking system with fuel consumption sensors, they were able to monitor the compressors on a real-time basis; leading to better accuracy in usage-based billing and happier customers. We are increasingly seeing such assets being offered “as-a-service” (a-a-S), and service-level-agreements (SLAs) come into play, which means real-time monitoring of an asset’s performance and health is hugely critical. Location based monitoring is also helping them optimize asset movement/re-assignment to nearby construction sites, reducing transportation costs and better utilization of revenue generating assets. Geo-fencing a group of these compressors also ensures an automated path to recovery by interfacing effectively with law-enforcement to retrieve stolen assets or when dispatch sends equipment to incorrect locations.

Another innovative company that makes Ultra HD drone-mounted cameras targeted for infrastructure monitoring has eliminated 1 in 3 tower (wireless, broadcast, and other aerial structures) climbs. Professional tower climbers have had to manually inspect structures to debug issues or monitor the health of assets on these towers. What used to be a manual, laborious, and time-consuming job (not to mention safety/need to wear a harness) to track and maintain towers has now become a routine and frictionless exercise, thanks to cloud-connected inspection photography, with the images/videos accessible to multiple parties instantaneously. Tower owners, tenants, and climbers can now get safer, faster, and cheaper inspections done from close-range and any imaginable angle!

Farming and Agriculture

A pig farmer in Austria keeps track of his animals, whether they are in the barn, or in the field. Advanced image processing can now not only count, but also estimate the weight of the pigs (without physical weighing the animals) and contact less temperature sensors help monitor the health of these assets. Other inexpensive livestock wearable electronic collars can now keep track of everything including cattle vitals, location of stray calves, etc., helping lower labor costs or visits to the vet. These wearable collars have sensors to monitor and catch health issues early before it becomes a larger problem such as the need for antibiotics or the spread of diseases within the herd. These devices communicate data periodically to barn based solar powered gateways which transmit it to the cloud for further processing and provide access to actionable dashboards via mobile device apps.

Retailing

Another interesting area is people counting in retail and public places leading to analytics that can help improve outcomes for both consumers and retail establishments. Large retailers that have

Another innovative company that makes Ultra HD drone-mounted cameras targeted for infrastructure monitoring has eliminated 1 in 3 tower (wireless, broadcast, and other aerial structures) climbs. Professional tower climbers have had to manually inspect structures to debug issues or monitor the health of assets on these towers. What used to be a manual, laborious, and time-consuming job (not to mention safety/need to wear a harness) to track and maintain towers has now become a routine and frictionless exercise, thanks to cloud-connected inspection photography, with the images/videos accessible to multiple parties instantaneously. Tower owners, tenants, and climbers can now get safer, faster, and cheaper inspections done from close-range and any imaginable angle!

Farming and Agriculture

A pig farmer in Austria keeps track of his animals, whether they are in the barn, or in the field. Advanced image processing can now not only count, but also estimate the weight of the pigs (without physical weighing the animals) and contact less temperature sensors help monitor the health of these assets. Other inexpensive livestock wearable electronic collars can now keep track of everything including cattle vitals, location of stray calves, etc., helping lower labor costs or visits to the vet. These wearable collars have sensors to monitor and catch health issues early before it becomes a larger problem such as the need for antibiotics or the spread of diseases within the herd. These devices communicate data periodically to barn based solar powered gateways which transmit it to the cloud for further processing and provide access to actionable dashboards via mobile device apps.

Retailing

Another interesting area is people counting in retail and public places leading to analytics that can help improve outcomes for both consumers and retail establishments. Large retailers that have